Integrated Heat Treating Solutions

What We Do

Integrated Heat Treating Solutions, LLC. (IHTS) is a metallurgy consultancy that offers part makers heat treating and forging solutions that deliver more added value to their product end users. IHTS uses a suite of proprietary Quench2FIT™ Technologies—sustainable heat treatments and forging practices, integrated with FEA modeling and part metrologies for a total lower cost of manufacture.

Z-Dimension Design, LLC., is an industrial design firm that specializes in enabling all the value from optimized heat treated part designs to be consistently realized in millions of production parts. Our consultants can also provide the enabling equipment for “leaner + greener” heat treatments that are fully integrated with more sustainable manufacturing, including optimal raw material sourcing for enabling the “Z-Dimension” of part design—easier recyclability.

Z-Dimension Designs also partners with new heat treating equipment makers and part handling automation that can enable a single-part flow from the manufacturing cell, or hot forging trim dies, through an optimal quench and temper heat treatment.

How We Help

Since heat treating practice is not usually one of the core competencies of most part makers, Akron Steel Treating Company has formed affiliations with consultants at IHTS and Z-Dimension Design, LLC.

IHTS's consultants form “Value Champion Teams” with our part making clients—collaborative part design and development teams that work with our clients, and our clients’ supply chain partners.

Our consultants seamlessly integrate three quarters of a century of AST’s practical heat treating experience, with all that is new in 21st century heat treating and forging practices—lessons learned from working with our over 1,200 different part making customers.

Recommendations

IHTS consultants recommend the optimal heating methods, whether by controlled atmosphere furnace, molten salt bath, vacuum furnace, or by induction or flame heating, as well as the optimal quench cooling methods (air/gas, molten salts, oil or intensive water quench).We also help you evaluate the heat treating services and equipment available to you, either within a part maker’s organization (their “captive” heat treat department), or at a high quality commercial heat treater, such as Akron Steel Treating. If a particular part heat treatment can be integrated into the part-machining cell or forging operation for single part flow, IHTS teaming partners can assist with the sourcing of the needed methods and equipment that are optimized to each part.

An Optimal Process for Optimal Products

When all the customers in the lean manufacturing value stream are in alignment with their "heat treaters," the results are better heat treated parts, at a total lower cost of manufacture. IHTS works to assure that each heat treating process is delivering you the best value.

For more information on Integrated Heat Treating Solutions and how our Z-Dimension industrial designs can help your production team deliver more added value to your part end users, check out our Resources.

Learn More About Integrated Heat Treating Solutions Modern Steels and Their Properties

Benefits Provided by IHTS and Z-Dimensions Designs

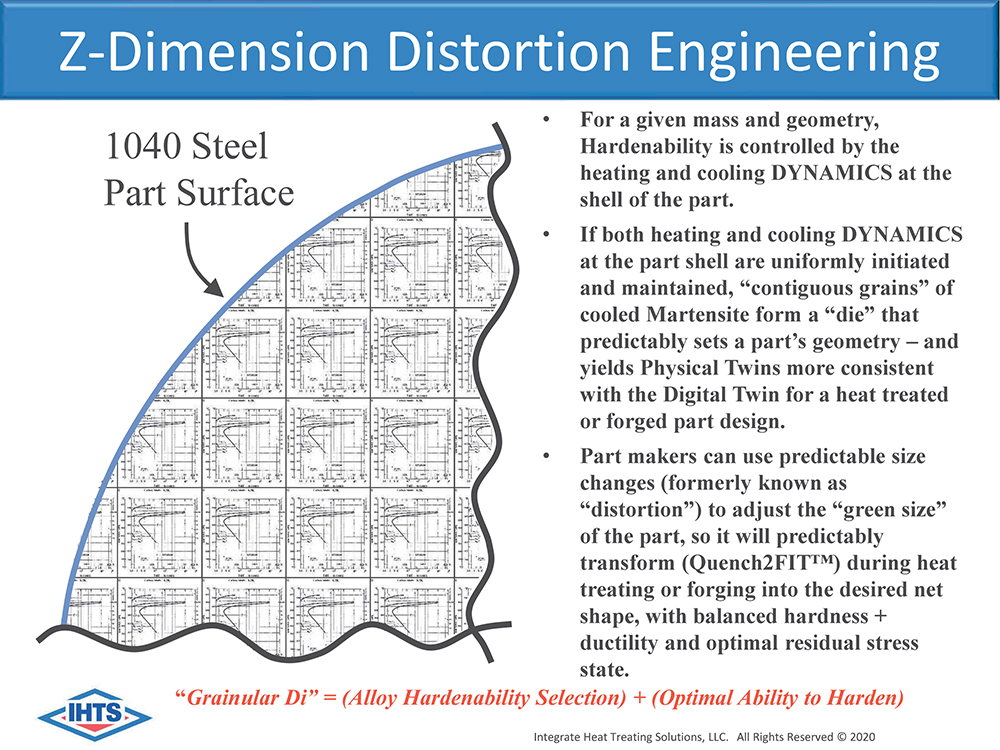

- Optimizing the mechanical properties for a given alloy’s “Hardenability,” while considering alloy cost and availability; coupled with the proper heat treatments for a given part mass and geometry—an optimal “Ability to Harden” or forge using our practical experience, buttressed with modern FEA and CFD modeling tools.

- Light weighting of part mass while delivering higher part strength, ductility and consistently longer part life into the existing product envelope.

- Reducing part distortion to eliminate millions of dollars of time and energy spent on post-heat treating processing with our Quench2FIT™ suite of technologies; new technologies that reduce hard turning, grinding, straightening, part cleaning, mechanical shot peeing, etc., as well as eliminate the hazards of batch oil quenching and facilitate “in the cell” heat treatments.

- Optimal part grain refinement for a given alloy using the least costly alloy of steel or ductile iron (IQDI®) for the “intended quench” that yields consistently uniform mechanical properties for a given part geometry and mass (for higher power density and longer lasting parts).

- Predictable size change after quench (low distortion) with uniform control of the three types of size change from heat treat quenching: thermal shrinkage, phase change expansion and unstable retained austenite.

- Optimal compressive surface stress state in the tempered part, as well as an optimal balance of hardness and ductility; the addition of a “Third Dimension” of compressive surface stress after heat treating yields longer cyclic fatigue life and lighter, higher power density, power transmission components.

- In-line, single part flow heat treating—even for case hardened parts (this can be done without the long, energy intensive, batch carburizing process) or direct from the forge intensive quenching (DFIQ).

- Alignment of lean + green company initiatives with heat treating by elimination of oil quenching hazards and by shortening, or full elimination of heating cycle times (DFIQ and Controlled Hardenability Steels for case hardened-core toughened parts without batch carburizing).

- Integration of modern computer modeling tools for lean part design, with the optimal material alloy selection, for more net shape, higher power density and longer wearing heat treated parts, all at a lower total cost of manufacture.

To integrate all our traditional and advanced heat treating technologies into the lean part manufacturing value stream, and to fully enable the above benefits, IHTS consultants can also provide heat treat metallurgy training.

Akron Steel Treating Company

336 Morgan Avenue, Akron, OH 44311

P.O. Box 2290, Akron, OH 44309-2290

We deliver within Ohio. ![]()

Toll-Free: 1-800-364-ASTC (2782)

Phone: 330-773-8211

Fax: 330-773-0772

Email: info@akronsteeltreating.com